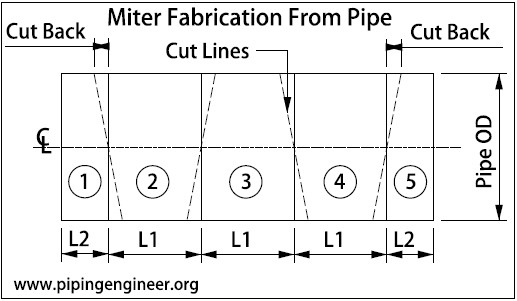

Here is formula to calculate required dimensions to fabricate miter from pipe. Each dotted cut line has a vertical reference line marked at following distances from pipe end. L: Distance of first and last reference line from pipe ends. L: Distance between reference lines.

Or check Plot Points to calculate and display lateral measurements at set increments around the pipe , to mark the cut line for the miter. Whay Wee Make The Offset Avoid The Obstrection Of Run. TABLE OF CONTENTS EXAMPLES EXAMPLE NO. Converting Slope (Inches Per Foot to Degree) EXAMPLE NO. Laying Out Laterals ( Miter Method) EXAMPLE NO.

For Parallel Piping EXAMPLE NO. Formula of Miter elbow with example. Method of Marking on Pipe surface and their error Method of joining pipe subscribe. I wanted to cut a deg miter on one end of the pipe and another at deg. Both cuts would not be on the same end.

This includes the diameter, wall thickness, angle, and offset. Comments piece degree elbow, center line center line, degree elbow fabrication formula , bend banane ka formula , Elbow miter cut formula one cut , elbow miter formula , how to cut elbow in any degree, In Hindi, miter bend banane ka formula , One cut elbow miter any degree, pipe degree. Supplying the custom miter cuts you want in the steel pipe you need.

We’ve told you a little about our state-of-the-art addition to our Houston-based steel pipe - cutting saws before. Now we’d like to give you a glimpse of how the Hem VT-140HA-saw works and the kinds of miter cuts it can make. A horizontal pipe aligned north-south takes a turn to the west and a drop in elevation.

At what miter angle do we cut the pipe to connect these two pieces? After being prepared for welding, one section of pipe should be rotated through 1degrees to form the desired angle, and then it should be tack-welded. Spacing should be slightly greater at the inside of the turn.

Figure 2-— Locating a cut on a pipe for any angle of a two-piece turn. This Coping Calculator is a handy tool that I use to create flat patterns for different pipes cuts, includes miter cut , pipes intersecting with variable angles or a pipe piercing through another pipe. Sometimes a degree pipe will need a degree right angle turn to come off.

Comments piece degree elbow, cut miter bend formula , any degree elbow miter formula , elbow miter theory, miter bend banane ka formula , miter elbow formula , pipe miter cut formula pdf, pipe miter cutting formula , पाइप का बैंड बनाने का. This video explain about Layout and Development of deg Pipe degree miter bend fabricate from pipe -Template) This channel explain about Reading. First video dedicated to the pipe The of a ferrule cut by a plane oblique to its axis is one of the fundamental. The precise miter angle of your moldings should be 45.

In the example shown, the inside corner is 90. In practice, this is pretty nearly a perfect corner. Included angle refers to the angle the two pieces meet in plan view. The angle is measured between the two pieces – 90° is a 4-sided box, 120° is 6-sides, etc.

Tube and Pipe Notching Calculator - Full Scale Printable Templates If Cut Tube Wall Thick is larger than the cut fits to the inside diameter of the tube, making a notch for welding. For a snug fit at the outside of the tube, enter Cut Tube Wall Thick and grind inside of tube to fit. Miter cuts on pipe, using a 90° weld elbow. Angle cutting pipe in the field.

Find your degreed angle. Length of full long side of elbow X the desired degree turn, divide that by 90. Length of the short side X the desired degree,. Measure the short side of the elbow.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.