Air liquide Welding proposes to go further with the comparative calculation that will help you to make up your mind to pick up the best value for your choice of welding process. Welcome to Welding Calculator Your practical tool to calculate filler metal consumptions for your welding processes We develop innovative products and efficient applications for you. Our Böhler Welding Calculator provides a programme that makes it easy for you to find out how much filler metal your processes require.

Welding Calculator The TOOL to calculate wire metal consumptions for your welding processes Please, follow THIS LINK in order to access our Welding Calculator. Total consumable required. Australian Welding Institute. Put ESAB expertise in the hands of your staff.

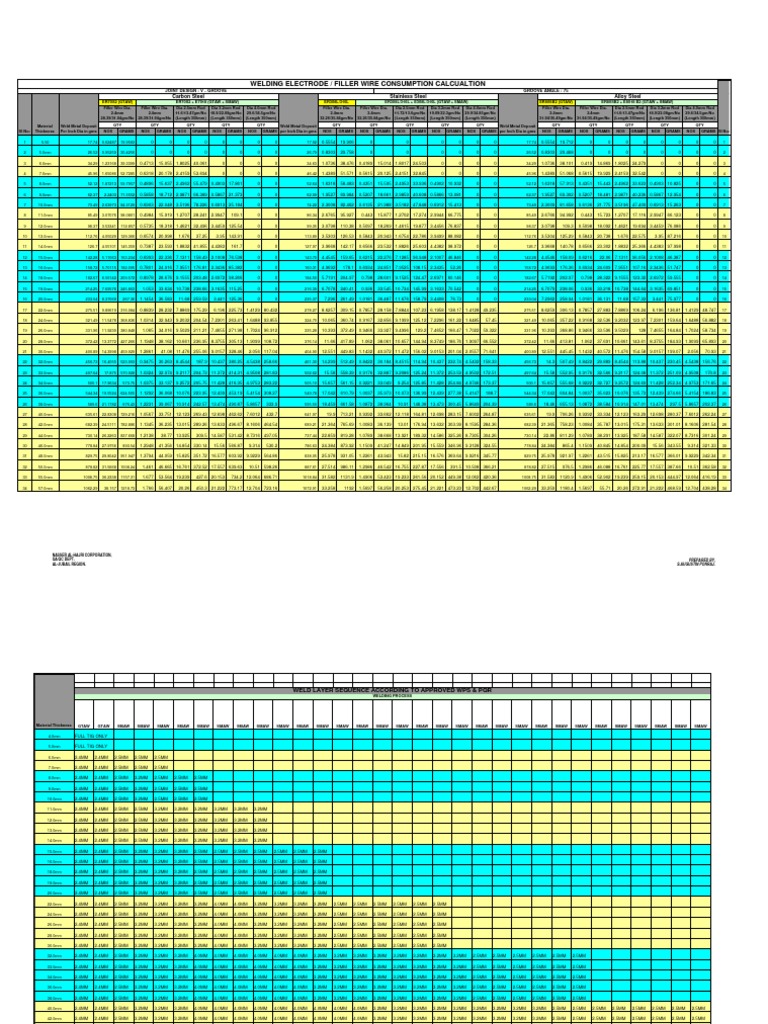

Search our extensive knowledge database for product information or for to common questions, interactive cost saving tools like our welding calculator , educational materials, training programs, valuable links, and more. Browse suggested weld parameter settings for Stick Welding , TIG Welding , MIG (Solid-Wire) Welding and MIG (Flux-Core) Welding. Figure shows the calculated consumption of welding consumables as a function of plate thickness, welding process, groove angle, and root opening for butt joints. With respect to fillet joints, Fig.

Businesses live and die on estimates ! I think the best treatment of weld cost estimation was done by Blodgett and is published in the Procedure Handbook of Arc Welding by the James F. Practical consumable consumtion for convex joint. If not changed from preset value the calculation will be made per meter weld. Need help with settings on your Longevity Welder? These welding calculators will enable you to set your machine perfectly every time. Based on the thickness, material, and power output of your machine, you will get some to try for your welding settings.

Select the current wire type and specifications, then select the information for the proposed weld metal you’d like to compare against. Weld Metal Cost Calculator. CIGWELD Pocket Guide App.

Calculating the volume of a weld is one of the first steps to be taken when estimating the cost of making a weld. With this information, and knowing the deposition rate of the process, it is possible to determine the arc time (the length of time that an arc is burning and depositing weld metal) and the amount of welding consumables required to fill the joint. This site uses cookies and other tracking technologies to provide you with our services, enhance the performance and functionality of our services, analyze the use of our products and services, and assist with our advertising and marketing efforts.

The steps taken to calculating welding costs and times are as follows: Calculate the volume of weld metal to be deposited. This is essentially based on the weld preparation and the length of weld. Calculate the mass of weld metal that needs to be deposite based on the density of the particular material that you are working with. To activate your FREE subscription today, simply select which newsletter(s) you would like to receive and complete the form below.

Miller respects your privacy concerns. We have made it easy for you to calculate your ROI by developing the calculator. Simply enter your welding program usage and see your calculated savings. Energy savings and weld metal calculators. These tools are designed to be used in the planning phase of your welding to help you save time and resources.

TIG Welding Calculator Tig Welding Calculators provides the information about Tungsten Electrode Diameter,Polarity,Amperage Range,Torch Cup Orifice Diameter,Gas,Gas Flow Rate,Filler Metal Diameter and Welding Speed. B- 2Estimating filler metal cost In the world of welding , many methods may be used to calculate the actual cost of welding for a given job or contract. ESAB Calculating Filler Metal Consumption. as PDF File (.pdf), Text File (.txt) or view presentation slides online. I use as a rule of thumb 1.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.