A pump is a device used to move fluids, such as liquids, gases or slurries. A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement,.

The first type of pump is the centrifugaldesign. Common rental pumps include standar trash and submersible models. The second type of pump is the positive displacement design, the most common of which is the diaphragm type. Different Types of Impeller. Semi-Open Impeller : The vanes are free on one side and enclosed on the other.

Enclosed Impeller : The vanes are located between the two discs, all in a single casting. There are main types of diaphragm pumps: Air-operated and Mechanical. They are also used for chemical transfer, de-watering underground coal mines , food manufacturing or where the liquid being pumped has a high solids content or high viscosity. Screw pumps are a special type of rotary positive displacement pump in which the flow through the pumping elements is truly axial. Screw pumps are high-volume, non-clog, atmospheric -head devices that can pump a variety of solids and debris in raw waste water without screening.

In the previous article we learned about the various characteristics, main parts and special features of the rotary pumps. In this article we will learn about the working of various types of rotary pumps, i. We will also learn how is the working of screw pump different from that of other types of pumps. Like other pump designs, it uses an impeller, which is a rotating blade to generate suction which then moves fluid through pipes. This type of pump is one of the most common in use today.

The rotating impeller creates what is known as centrifugal force, giving this pump design its name. MECHANICAL PUMPS In mechanical pumps , the gas present in a vacuum system is transferred from a low pressure to a higher pressure region. In order to be efficient, the pump has to provide simultaneously a finite pumping speed and compression.

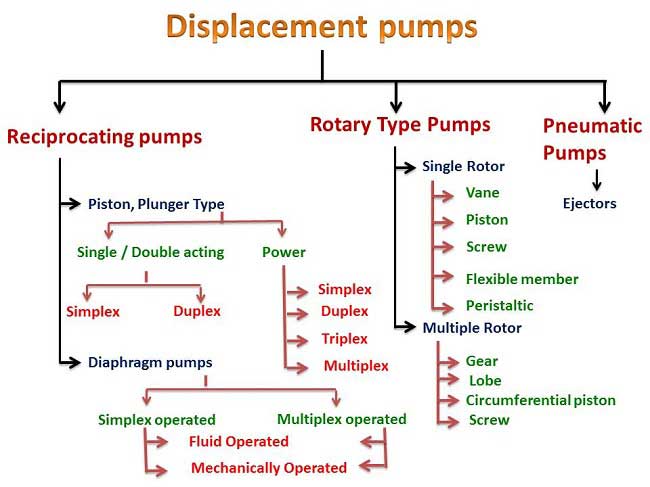

What type of pump is main L. STATE the purposes of the following centrifugal pump components: a. MECHANICAL ENGINEERING – Types and Performance of Pumps and Compressors – Essam E. SELECTION OF PUMP TYPE AND PUMP 4. Positive displacement pumps These types of pumps are built as reciprocating, or as rotary machines. This section introduces the various types of pumps and motors that are available for hydraulic systems. Since pumps and motors are similar in many cases, just one shall be discussed.

There are two main categories of pumps and motors - hydrodynamic and positive displacement 4. Hydrodynamic - Two basic types exist - centrifugal and turbine pumps. The impeller has a uniform blade length, b, of in. Pumps play a fundamental role in all types of buildings, since they simplify the movement of fluid substances.

Figure 3: Typical centrifugal pump. Most pumps in residential and commercial locations handle water, and they have applications in many building systems: fire pumps provide a pressurized water supply for firefighters and automatic sprinklers, booster pumps deliver potable water to upper floors in high-rise constructions. These types pumps used for the application of sewage, sludge, scum, clarifier thickener underflow. It can be applied for transfer and for metering service.

Such pumps are available in single- and multi cylinder models. CENTRIFUGAL PUMPS, contd. Distance the water stream travels tangent to the circle = f (Vr)4. Volume flow from hole = f (Vr)5.

Centrifugal Pumps: Working Principal1.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.