What are the three types of impellers? What is the difference between an impeller and a fan? How efficient are impeller washing machines? Open impellers have the vanes free on both sides. The vanes are located between the two discs, all in a single casting.

There are two types of impellers, depending on the flow regime created (see figure): Axial flow impeller.

Impeller types can be radial , mixed flow , axial and peripheral and are selected on the basis of the pump design and the application. The number of vanes will affect the efficiency, in general more vanes are more efficient. Impeller Power: The power required to run a specific impeller with a given diameter at a given speed. Generally most efficient because it produces the maximum pumping with the lowest shear. Semi-open impellers have vanes that are attached to a single plate, leaving the other side of the impeller exposed to the interior of the pump housing.

Ideal for applications where shear is the primary. Single suction : In single-suction impeller , liquid enters the center of the impeller eye from only one direction. View this side-by-side comparison to learn how washing machines with impellers stack up against washing machines with agitators.

They are typically used in small-diameter, inexpensive pumps and pumps handling suspended solids. A single-suction impeller allows liquid to enter the center of the blades from only one direction. Impellers can be either single suction or double-suction. Selecting an impeller based on the unique needs of the application is vital in ensuring the production of an equal mixture. When you boil them down to the most fundamental components, pumps are made up of two components: An impeller which creates velocity through rotation, And a casing which converts velocity into pressure.

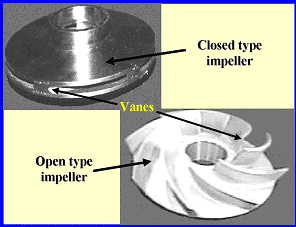

There are different types of impellers and different types of casings. Split-case pumps are the most common type of pump with a double suction impeller. Closed impellers have a back and front wall around the vanes, to increase strength.

These types of impellers are commonly found in clear liquid applications. The closed- impeller type is the most widely used type of impeller for centrifugal pumps handling clear liquids. Different Types of Impeller.

They rely on close-clearance wear rings on the impeller and on the pump housing. The wear rings separate the inlet pressure from the pressure within the pump, reduce axial loads, and help maintain pump efficiency. For applications that require some degree of both turbulence and flow, though, pitched blade impellers are a great solution.

Impeller flow designs can take on three distinct types : axial, radial, and mixed. Slurry applications can be especially hard on the impeller of your pump because of their abrasive nature. In order for your process to operate efficiently and stand up to the test of time, you must choose the proper impeller.

So Rushton impeller is today the most common generic term applied to flat-bladed or disk-turbine impellers (e.g., Figure 2).

Their blades are flat and set vertically along an agitation shaft, which produces a unidirectional radial flow. The most commonly used pump type however is the centrifugal pump. This impeller when spins, transfers energy to the fluid with the help of centrifugal force. Centrifugal pumps come with an impeller. It directs the water to the discharge point.

A type of centrifugal pump that can pump solids is known as trash pump. In a single suction impeller , fluid enters through one side only Double suction impellers are designed to. The radial type pumps are used for the application of high head and low discharge.

In radial flow pumps ratio of impeller outside Dia ( D2) to eye Dia ( D1) is or more and impeller having narrow width. Mixed Flow : The flow direction is partly axial and partly radial. Hence has a result the flow is diagonal.

Semi-closed impellers are usually used with liquids or products that have solids. Earlier, impellers generally were divided into two categories open and closed. But these days, there is also a third type available. It is called a semi open impeller.

Here are a few differences between the open and closed impeller : The open impeller has a series of vanes attached to a central unit. This is done for the mounting on the shaft. An impeller is a low-profile rotating hub that replaces the agitator in some washing machine models.

The vanes of the impeller create turbulent currents in the wash water as the impeller rotates. In theory, these currents move the clothes through the water and clean them without the impeller making physical contact with the clothes.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.